In its quest to incorporate high-tech into its manufacturing processes, ENVIRA acquires specialized equipment to produce the electronic boards for its Internet of Things devices.

Thanks to this new asset that has been incorporated into the IoT workshop, a qualitative leap has been made in the manufacturing chain of the Nanoenvi range, achieving the manufacture of high-quality printed electronic circuits.

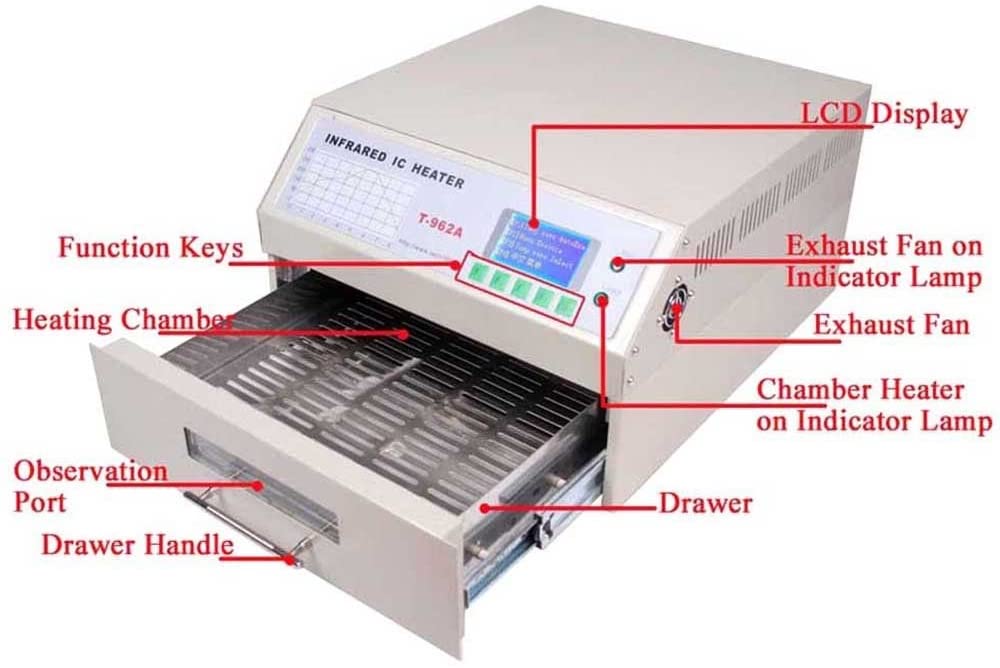

The equipment purchased is the T962-A infrared reflow oven with high-tech PCB soldering, which will reduce costs and time in the manufacturing process.

Why has this equipment been incorporated into our production chain?

As specialists in the manufacture of IoT equipment, ENVIRA technicians are aware that the market is increasingly demanding smaller devices, so hardware must be integrated into a smaller space.

The T962-A Infrared Reflow Oven not only simplifies the difficulty of assembling electronic components on smaller printed circuit boards (PCBs), it also allows to plan larger-scale production.

Features and technical data

- The T962-A is a standalone microprocessor-controlled IC heater and solder repair station.

- It uses up to 1500 watts of energy-efficient infrared heating and air circulation to re-flow the weld over a large 300 × 320mm area.

- The parameters of the eight welding cycles are preset.

- Welding cycles are the selected keyboard and the progress displayed on the T962-A LCD.

- A single drawer with a window allows mounting inside the heating chamber.

- The entire soldering process is automatically completed from preheating, soaking, and refluxing through cooling.

- The T962-A can solder small parts of double-sided or more sketch printed circuit boards, ie. : CHIP, SOP, PLCC, QFP, BGA, etc .; It can be used in the gum of the solid product, rotating the hot aging circuit board, keeping the PCB board and so on.

|

Supply voltage |

AC220V/50 ~ 60Hz |

| Welding |

180mm x 235mm |

|

Nominal power |

800 W |

|

Temperature range |

0 ~ 280 ℃ |

| Function |

Drying thermostat |

|

Cycle time |

1 ~ 8 min |

|

On-line operation |

NO |

|

Type of heating |

Infrared heating |

|

Storage capacity curve machine |

8 |

|

Weight |

8 kg |

| Packaging dimensions (length x width x height) |

38*24*38 cm |