Industrial operations and processes generally involve a series of physico-chemical reactions that result in emissions of pollutants, the release of which can affect the quality of air, water and soil.

Emissions are the continuous or discontinuous release of pollutants into the environment. In particular, the term “industrial emissions” refers to releases resulting from various industrial activities: energy production, chemical production, cement production, metallurgy, etc., among many others.

Their origin is very diverse and the classification of the types of industrial emissions can be made from different angles, such as the type of polluting substance, the industrial activity or the emitting focus.

Industrial emissions by type of pollutant

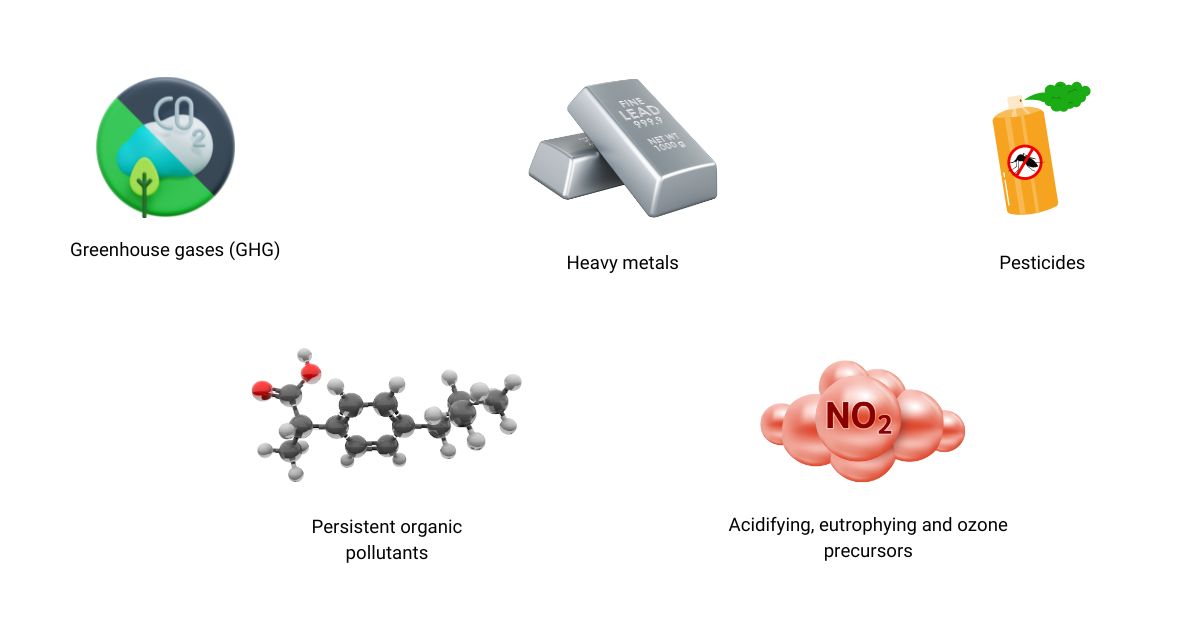

The Pollutant Release and Transfer Register (PRTR) allows us to find out which are the most common emissions from industry, grouped by type of pollutant. In this way we find

- Greenhouse gases

- Persistent organic compounds

- Acidifying, eutrophying and ozone precursors

- Heavy metals

- Pesticides

Greenhouse gases (GHG)

This classification refers to the emission of those pollutants that favor global warming, such as water vapor (H2O), carbon dioxide (CO2), nitrous oxide (NO2), methane (CH4), ozone (O3), hydrofluorocarbons (HFCs), perfluorocarbons (PFCs) and sulfur hexafluoride (HF6), the latter being of anthropogenic origin.

Persistent organic pollutants (POPs)

This group includes highly toxic, bioaccumulative and highly persistent chemicals with the capacity to be transported over long distances, posing a significant threat to the environment and human health.

Some examples of these POPs are polycyclic aromatic hydrocarbons (PAH) such as Benzo(a)pyrene, Hexachlorobenzene, PCB, Hexabromobiphenyl…

Acidifying, eutrophying and ozone precursors

Emissions of these pollutants have a significant impact on the quality of air, water and soil and on human health.

Acidifying gases such as SO2, NOx and NH3 emitted into the atmosphere undergo a chemical transformation (sulphuric or nitric acid, ammonium sulphate and ammonium nitrate) that causes severe damage to natural ecosystems sensitive to acidification.

On the other hand, NOx and NH3 cause an abnormal enrichment of nutrients in surface waters, leading to a loss of quality, oxygen depletion, toxins…

Finally, ozone precursors such as non-methane volatile organic compounds (NMVOCs), CO, NOx and methane (CH4) are substances that favour the formation of tropospheric ozone, an important factor in controlling climate change.

There are also other substances of anthropogenic origin whose emissions deplete the ozone layer, such as halogenated hydrocarbons.

Heavy metals

Various industrial activities, such as the burning of fossil fuels, the processing of metals and minerals or waste management, can lead to emissions of heavy metals such as arsenic, cadmium, chromium, copper, mercury, lead, cobalt, nickel…..

These heavy metals are associated with environmental pollution and potential toxicity and ecotoxicity.

Pesticides

Although the main function of pesticides is to improve agricultural yields, control insect vectors of disease and protect public health, some of them can have very negative effects on human health and the environment, so it’s necessary to control emissions of pesticides such as alachlor, aldrin, chlordecone, endosulfan, mirex, toxaphene, etc.

Types of emissions by industrial activity

If we are interested in knowing which industries generate the most emissions in their processes, the PRTR provides us with the following classification:

- Combustion/energy facilities: mainly emissions of SO2, NOx and fine particulate matter (PM).

- Metal production and processing: emissions mainly of heavy metals such as lead, mercury, cadmium and arsenic, as well as nitrogen oxides and sulfur dioxide.

- Mineral industries: mainly release particulate matter, sulfur dioxide and other compounds resulting from the extraction, crushing, processing and transport of metallic and non-metallic minerals.

- Chemical industry: this industry mainly emits volatile organic compounds, acid gases, NOx and SO2.

- Waste and wastewater management: the decomposition of organic waste generally releases methane (CH4) and carbon dioxide (CO2), in addition to volatile organic compounds, sulfur and ammonia compounds during the treatment and composting processes, and other substances such as persistent organic compounds (POPs).

- Wood-based industry (paper and cardboard): very similar to the chemical industry, it releases into the atmosphere mainly SO2, VOCs, particles and other toxic substances for the bleaching and treatment of wood.

- Livestock and intensive agriculture: pollutants are mainly NH3, VOCs, greenhouse gases and other pollutants from manure and organic waste management.

- Animal and plant products from the food and beverage industries: These industries are the main emitters of VOCs, greenhouse gases, vapours and particulates.

- Other activities such as the textile, plastics, cement and glass industries, among others, are also included in the emission-producing industries.

In Spain, these industrial activities can in turn be classified as potentially air polluting activities, which are divided into 3 main groups (Group A, B and C) according to their pollution potential.

In this way, Group A activities are those that have a greater impact on the environment, Group B activities are those with less polluting potential but with a relevant contribution to air pollution, and finally Group C activities are those that are sources of polluting emissions to the atmosphere but do not generate emissions as relevant as those included in the previous groups.

The complete catalogue can be found in Royal Decree 100/2011, which updates the catalogue of potentially polluting activities and establishes the basic provisions for its application.

Emission types by source

In addition to the two previous classifications based on the type of pollutant and the industrial activity, industrial emissions can be differentiated according to their focus.

Point emissions

Point emissions are those that come from specific and well-defined sources within an industrial facility, are easily identifiable and can be controlled with specific technologies.

Within this type are channeled emissions, which are those where the release of pollutants is directed or transported to the environment through stacks or pipes.

Ducted emissions allow better control and management of the pollutants released, thanks to continuous emission monitoring systems that allow adequate control of compliance with environmental regulations.

Non-point emissions

Non-point emissions are those emissions that do not have a specific identifiable source, but come from multiple sources dispersed throughout a facility or industrial area, but can be clearly identified and measured.

These emissions can be more difficult to control and monitor due to their dispersed nature – such as emissions of volatile organic compounds in a chemical plant – and therefore the use of continuous perimeter monitoring systems allows the data collected to be analysed and compliance with emission limit values to be ensured at all times.

Fugitive emissions

Diffuse emissions are the result of industrial processes that release pollutants into the air, soil or water over a wide area (they do not originate from a single, well-defined point) and are therefore less concentrated and more dispersed than canalised emissions.

Fugitive emissions

These are unintentional releases of pollutants that occur due to accidental leaks or escapes from equipment, piping, valves or material storage and handling systems.

These emissions are an important part of global emissions and their main problem is that when they occur unintentionally, they have a high impact on business profitability and the environment.

For more information, read our article “Detecting and controlling fugitive emissions in the process industry“.