A variety of industrial activities generate emissions as part of their regular operations. Fugitive emissions represent an important part of global emissions and are defined, according to the European Standard EN15446:2008, as “Emission to the atmosphere caused by the loss of airtightness of a device, which is designed to be airtight”.

These emissions occur at different stages of production in many industries – even outside the scope of the production process such as extraction, transport or distribution – and are regulated in order to comply with established environmental limits.

The problem with fugitive emissions is that, unlike other types of emissions, they are unintentional and have a major impact on business profitability and the environment.

In fact, they account for between 5% and 15% of total greenhouse gas emissions, a percentage that varies depending on the type of industry.

What are fugitive emissions?

Fugitive emissions are a type of unchannelled pollutant emissions (unintentional releases) that occur during the production, transport, storage or processing of substances.

The substances that generate fugitive emissions in industry can vary widely depending on the type of processes and activities carried out, but are generally associated with hydrocarbons, VOCs, toxic gases such as ammonia, chlorine or hydrogen sulphide, solvent vapours or acid gases such as SO2 or NOx.

There are also fugitive emissions of particulate matter from minerals such as coal, chemical powders, metal dusts, agricultural products or construction materials. It is clear that leak detection is essential to ensure that emissions are kept within permitted limits and to prevent the uncontrolled release of hazardous substances into the atmosphere.

To control fugitive emissions, companies must implement early detection strategies and leak control systems.

Leak detection and monitoring systems and equipment

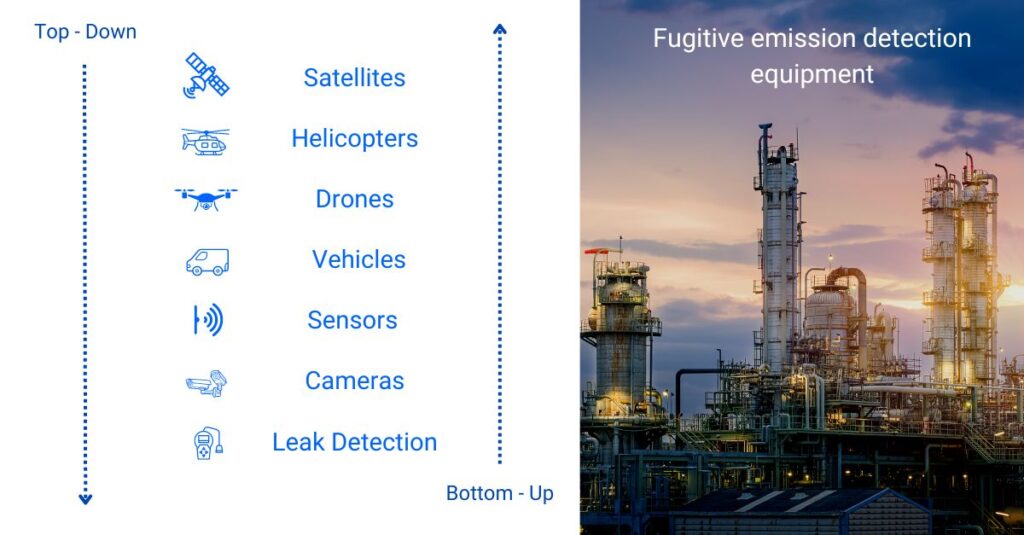

There are various leak monitoring techniques of varying degrees of technical complexity, classified according to the distance they are located from the source of the emission: “top-down” or “bottom-up”.

Top-down monitoring is carried out from the farthest part of the source and provides information on unexpected leaks, which in many cases are very significant and cannot be identified with a bottom-up approach.

In contrast, bottom-up monitoring of emissions close to the point of leakage provides relevant information on the specific source of the emissions and, more importantly, on concrete measures that can be taken to reduce them.

Satellites

One of the most advanced techniques in recent years. It belongs to the “top-down” classification and in this case is carried out from the point furthest away from the source.

Satellites can make regular and systematic observations, allowing long-term, uninterrupted monitoring of large and remote areas. This greatly facilitates the calculation of the total emission rate and the identification of super-emitters.

On the other hand, they have limited image resolution and atmospheric conditions (e.g. clouds) can affect the quality of satellite images.

Helicopter

It is more practical and economical to use than satellites and allows greater spatial resolution than satellites, which is an advantage for identifying and quantifying emission sources in more detail, and also allows a large number of kilometres per day to be covered and problem areas to be detected.

However, it is still an expensive option compared to other technologies and has certain limitations in terms of geographical coverage due to time and distance constraints.

Drones

There are different configurations, they allow detection by laser or optical means (OGI), they are very stable and one of their main advantages is that they allow scheduled flights over an installation, thanks to which it is possible to detect which equipment or area has leakage problems.

On the other hand, flight time is limited and there are certain structures that do not allow overflight or proximity to certain components.

Vehicles or Mobile AQMS

They are very useful in urban environments to locate problem areas quickly and effectively.

If these vehicles are also equipped with type-approved air pollution monitoring equipment (as in the case of mobile monitoring stations), it is possible not only to detect fugitive emissions but also to carry out accredited measurement campaigns with continuous real-time data.

Fixed-point sensors

The Nanoenvi EQ portable monitoring station equipped with different sensors allows, thanks to its lightweight and compact design, continuous monitoring of particulate matter and various gases at points where fugitive emissions are likely to occur.

It also has a data visualisation platform that allows real-time alerts to be generated in case any pollutant exceeds the established limits.

In the case of needing type-accredited instrumentation, compact air quality monitoring stations (AQMS) are a good alternative, as they are designed with the same features as fixed stations but thanks to their compact size, they can be located in places where there is not much space available.

Leak detection and repair (LDAR technology)

In this case, operators are equipped with detection instruments in accordance with the regulations, carry out the appropriate measurements and repair in case of leakage.

This measurement method is supported by EPA Method 21 in the Americas and EN 15446:2008 at European level.

Major industries with fugitive emissions

The industries most affected by fugitive emissions tend to be those using chemicals or high temperature processes, such as:

- Petrochemical industry

- Chemical and pharmaceutical industries

- Power generation industry

- Metallurgical industry

- Paper industry

- Textile industry

In these industries, process and fugitive emissions are regulated by the conditions of the relevant Integrated Environmental Authorisation (IEA) and the applicable air pollution standard.

This implies the need to effectively monitor and control the release of pollutants during the planned industrial operations.

In this sense, spanish Law 34/2007, of 15 November, on Air Quality and Protection of the Atmosphere, and its subsequent updating of the catalogue in accordance with Royal Decree 100/2011, of 28 January, adopts a comprehensive approach, including all anthropogenic emission sources and identifying those activities that it considers should be subject to specific and individualised control.